Introduction

In the oil and gas industry, the term wireline is widely used during well intervention and well control operations. This technology plays a crucial role in gathering subsurface data and performing maintenance or intervention work without stopping production.

This article explains what wireline is, its types, and how it supports safe and efficient well control operations.

What Is Wireline?

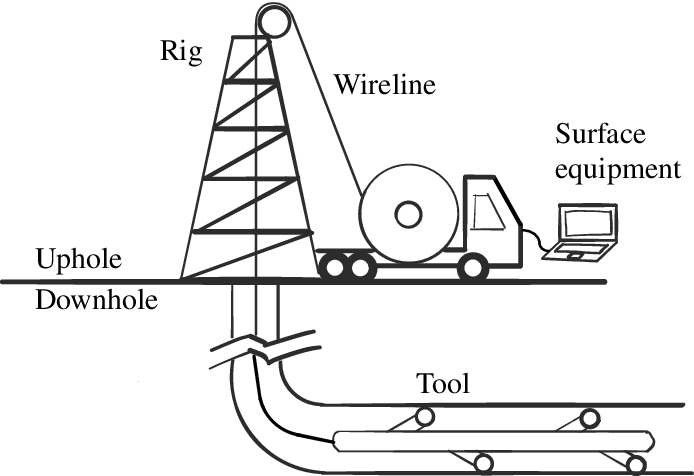

Wireline refers to a steel cable (sometimes containing electrical conductors) used to lower and retrieve tools or instruments into the wellbore.

It allows operators to perform a wide range of tasks such as:

-

Collecting formation evaluation data (logging)

-

Installing or removing downhole equipment

-

Cleaning or opening blocked well paths

-

Conducting light intervention without using a full drilling rig

In short, wireline gives engineers the ability to communicate and interact with the well from the surface using a controlled cable system.

Types of Wireline: Slickline and Electric Line

1. Slickline

A slickline is a single-strand steel cable with no electrical conductor. It is mainly used for mechanical tasks inside the well, such as:

-

Replacing valves, plugs, or packers

-

Cleaning sand, scale, or debris

-

Fishing or retrieving stuck tools

2. Electric Line (E-Line)

An electric line, or e-line, contains one or more electrical conductors inside the wire, enabling data transmission and real-time communication with downhole tools.

Typical uses include:

-

Logging operations (collecting pressure, temperature, and resistivity data)

-

Perforating casing sections

-

Monitoring well conditions and equipment status

The Role of Wireline in Well Control

In well control, wireline operations are critical for maintaining safety and preventing pressure-related incidents such as kicks or blowouts.

Here are the main functions:

-

Monitoring Well Pressure

-

E-line tools provide real-time pressure and temperature data from the wellbore.

-

This information helps detect early signs of abnormal formation pressure or fluid migration.

-

-

Maintaining Well Integrity

-

Wireline tools can inspect casing, tubing, and cement bond conditions to identify potential integrity issues that could compromise well control.

-

-

Safe Perforation Operations

-

Controlled wireline perforating systems allow operators to perform underbalanced perforation while maintaining surface pressure control.

-

-

Rigless Well Intervention

-

Since wireline units are compact and mobile, they enable cost-effective and safe interventions without requiring a large drilling rig.

-

Wireline Safety and Pressure Control Equipment

Wireline pressure control equipment is essential to maintain well control during wireline operations. The main components include:

-

Wireline BOP (Blowout Preventer) → seals the well in case of unexpected pressure

-

Lubricator → a high-pressure chamber used to insert wireline tools safely into the well

-

Grease Injector Head → prevents gas or fluids from escaping while the wireline moves

-

Stuffing Box → provides sealing around the cable to control well pressure

These systems ensure operators maintain pressure integrity and operational safety at all times.

Wireline Well Control Training and Certification

Personnel performing wireline operations must be trained and certified in wireline pressure control and well control procedures.

Recognized training programs include:

These courses cover topics such as well pressure theory, equipment operation, shut-in procedures, and emergency response.

Conclusion

Wireline technology is an essential part of modern well intervention and well control operations. It allows oil and gas companies to safely access the wellbore, gather critical data, and perform maintenance without major interruptions.

Understanding the principles of wireline operations, pressure control equipment, and safety standards helps professionals prevent serious incidents like well kicks and blowouts.

Investing in wireline well control training ensures both operational safety and long-term well integrity.