Introduction

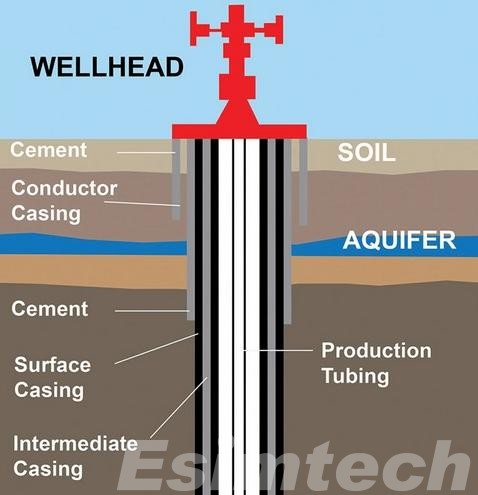

Cementing plays a crucial role in oil and gas well construction. Engineers use cementing to secure the steel casing inside the wellbore and to isolate one formation from another. A well-executed cementing job maintains well integrity, prevents fluid migration, and strengthens the entire well structure.

Principles of Cementing

The main goal of cementing is to create a hydraulic seal between the casing and the surrounding formation. This seal blocks unwanted formation fluids from entering the wellbore and gives mechanical support to the casing.

Key Objectives

-

Achieve zonal isolation between different formations.

-

Support and protect the casing from external pressure and corrosion.

-

Stop gas or fluid migration to the surface.

-

Maintain wellbore stability during production.

To reach these goals, engineers adjust the cement slurry’s density, viscosity, setting time, and compressive strength.

Cementing Procedure

1. Slurry Design

Engineers design the cement slurry by mixing cement, water, and specific additives. They test the mixture in a lab to match downhole conditions such as pressure and temperature.

2. Casing Preparation

Before pumping cement, the crew cleans the casing and wellbore with spacers and mud flushes. This cleaning process removes drilling mud and helps the cement bond tightly to the casing and formation.

3. Cement Placement

The team pumps the slurry down the casing and pushes it into the annulus between the casing and formation. They use top or bottom plug systems to separate fluids and ensure complete displacement.

4. Displacement and Waiting on Cement (WOC)

After placement, the crew waits for the cement to harden. This waiting-on-cement period allows the cement to gain enough strength before the next drilling or completion step.

Materials Used in Cementing

1. Cement Types

Most operations use API Class G or H Portland cement, designed for high-temperature and high-pressure environments.

2. Water

Water activates cement hydration and controls workability. Engineers carefully set the water-to-cement ratio to manage the slurry’s strength, setting time, and density.

3. Additives

Cement additives fine-tune the slurry’s performance:

-

Accelerators: Shorten setting time (e.g., calcium chloride).

-

Retarders: Slow setting for high-temperature wells.

-

Dispersants: Improve flow and reduce viscosity.

-

Fluid Loss Agents: Keep the slurry from losing water to the formation.

-

Expanding Agents: Offset shrinkage as the cement sets.

Importance of Proper Cementing

Poor cementing can lead to gas migration, casing damage, or production loss. In severe cases, it may cause blowouts or require expensive remedial jobs.

By designing the slurry correctly and following proper procedures, engineers ensure long-term well integrity and safety.

Conclusion

Cementing in oil and gas operations forms the backbone of well integrity. When engineers understand the principles, execute the procedure correctly, and choose the right materials, they secure the casing and maintain stable production throughout the well’s life cycle.